Understanding the technology transforming industrial systems

The Industrial Internet of Things (IIoT) refers to the use of smart sensors, devices, and connected systems in industrial settings such as manufacturing, energy, transportation, agriculture, and more. IIoT enables real-time data collection, intelligent automation, predictive maintenance, and optimized operations by connecting machines, devices, people, and processes across an industrial network.

While the term Internet of Things (IoT) typically refers to consumer devices like smart thermostats or wearable fitness trackers, IIoT is specifically focused on industrial applications where the stakes are higher — including equipment uptime, safety, efficiency, and production output.

IIoT vs IoT: Key Differences

| Feature | IoT (Consumer) | IIoT (Industrial) |

|---|---|---|

| Application Area | Smart homes, wearables, consumer apps | Manufacturing, logistics, energy, agriculture |

| System Complexity | Simple and user-friendly | Complex, large-scale systems |

| Reliability Needs | Moderate | High (downtime can be costly/dangerous) |

| Latency Requirements | Flexible | Extremely low latency (real-time needed) |

| Security | Standard encryption | Advanced security, compliance standards |

| Data Use | Convenience and personalization | Operational efficiency, safety, cost savings |

Why the Industrial Internet of Things Matters

The rise of the Industrial Internet of Things is being called the Fourth Industrial Revolution (Industry 4.0). With IIoT, industries can move from reactive to predictive and autonomous operations. This means fewer breakdowns, faster decision-making, and smarter resource allocation — all powered by data.

According to Accenture, the IIoT could add $14.2 trillion to the global economy by 2030. From reducing machine downtime to improving supply chain transparency, IIoT is reshaping how companies operate.

“IIoT will enable a level of operational visibility and control never before possible. The data collected from connected machines will become a gold mine for optimizing productivity and innovation.”

— McKinsey & Company

Core Components of IIoT

- Smart Sensors – Devices that monitor temperature, vibration, pressure, etc.

- Edge Devices & Gateways – Convert raw sensor data into actionable insights near the source.

- Connectivity Infrastructure – Wired/Wireless communication like 5G, Ethernet, LPWAN, Wi-Fi.

- Cloud Platforms – Store and process massive amounts of real-time and historical data.

- Analytics Engines – AI/ML tools for predictive maintenance, pattern detection, optimization.

- User Interfaces – Dashboards for operators, engineers, and executives to make decisions.

Industries Where IIoT is Transforming Operations

- Manufacturing – Smart factories with machine learning and robotics.

- Oil & Gas – Monitoring pipeline conditions and equipment health remotely.

- Energy & Utilities – Grid monitoring, smart meters, load forecasting.

- Transportation & Logistics – Fleet tracking, route optimization, cold chain monitoring.

- Agriculture – Precision farming with drones, irrigation sensors, and yield prediction.

Frequently Asked Questions (FAQs)

What is the main purpose of the Industrial Internet of Things (IIoT)?

The main purpose of IIoT is to connect industrial devices and systems to collect data, optimize operations, enhance safety, reduce downtime, and increase efficiency.

How is IIoT different from IoT?

IIoT focuses on mission-critical industrial systems with high reliability and real-time data needs, while IoT usually refers to consumer-focused devices and applications.

Which technologies enable IIoT?

Key technologies include sensors, cloud computing, edge computing, artificial intelligence, machine learning, and high-speed connectivity like 5G.

How Does the Industrial Internet of Things (IIoT) Work?

Exploring the architecture, processes, and flow of data

The Industrial Internet of Things (IIoT) functions through a multi-layered architecture that connects machines, sensors, people, and systems to collect, transfer, and analyze data — all in real-time or near-real-time. These technologies work together to make industrial operations smarter, faster, safer, and more cost-effective.

H2: IIoT Architecture: The 4 Key Layers

To understand how IIoT works, it’s essential to break it down into its foundational layers:

H3: 1. Perception Layer – Data Acquisition

This is where data is generated. The perception layer includes:

- Sensors and actuators (e.g., temperature, vibration, humidity, flow sensors)

- RFID tags, barcodes, GPS trackers

- Connected machinery

These components monitor physical conditions and convert them into digital signals that can be analyzed. For example, a sensor on a manufacturing line might detect heat levels to prevent overheating.

H3: 2. Network Layer – Data Transmission

This layer handles the transfer of data from edge devices to central systems or the cloud using:

- 5G, LTE, Wi-Fi

- LPWAN (Low Power Wide Area Networks) like LoRaWAN or NB-IoT

- Wired Ethernet or fiber connections

Reliability and low latency are crucial, especially in time-sensitive applications like assembly lines or power grids.

H3: 3. Processing Layer – Data Management and Analysis

At this stage, data is processed, filtered, and analyzed. It may happen:

- At the edge (edge computing) for quick, local decisions

- In the cloud (cloud computing) for deep, historical analysis

This layer uses AI, machine learning, and big data platforms to identify patterns, make predictions, and offer recommendations.

Example: Predictive maintenance tools can flag a motor that’s likely to fail in two weeks, allowing the company to replace it before downtime occurs.

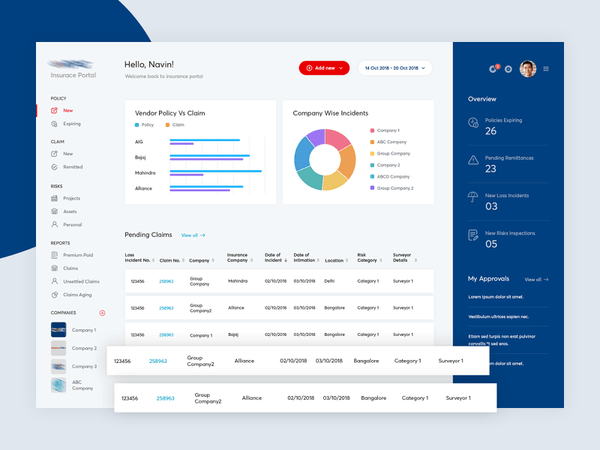

H3: 4. Application Layer – Insights and Control

This is the end-user interface, where engineers, operators, and executives access dashboards or alerts to make decisions.

- SCADA systems, HMI dashboards, mobile apps

- Alerts for critical issues (e.g., overheating motor, gas leak)

- Trend visualizations and historical reporting

- Automation triggers (e.g., reduce machine speed during high vibration)

Data Flow Example in an IIoT System

Here’s how a real-world example in a smart factory might look:

| Step | Description |

|---|---|

| 1 | Vibration sensors detect abnormal levels on a machine. |

| 2 | Data is transmitted via Wi-Fi to an edge device. |

| 3 | Edge computing platform analyzes the data locally. |

| 4 | An AI algorithm predicts motor failure in 72 hours. |

| 5 | The maintenance team receives a real-time alert. |

| 6 | A work order is automatically created in the CMMS (maintenance system). |

Technologies That Power IIoT

- Edge Computing – Enables fast, local decision-making at the machine level.

- Cloud Platforms – For large-scale data storage and analytics (e.g., AWS IoT, Microsoft Azure, Google Cloud IoT).

- AI & Machine Learning – Enables predictive insights and automation.

- Digital Twins – Virtual replicas of physical assets for simulation and optimization.

- Blockchain – Secures data integrity, especially in supply chains.

- Cybersecurity Protocols – Protect data from breaches, a critical aspect of IIoT.

“The real-time insight offered by IIoT allows businesses to reduce downtime by up to 50%, improve throughput, and enhance quality.”

— GE Digital Whitepaper

Frequently Asked Questions (FAQs)

What is the role of edge computing in IIoT?

Edge computing processes data locally at or near the data source, allowing for faster decisions, reduced latency, and lower bandwidth use — which is critical in industrial environments.

How do IIoT systems communicate?

IIoT systems use wireless (e.g., 5G, Wi-Fi) and wired (e.g., Ethernet) networks to transmit data from devices to cloud platforms or local processing systems.

Can IIoT work without internet access?

Some aspects, like edge processing, can work offline. However, full functionality — especially cloud analytics — requires internet connectivity.

Benefits of the Industrial Internet of Things (IIoT)

Why industries are rapidly adopting IIoT technologies

The Industrial Internet of Things (IIoT) offers a wide range of benefits across sectors, driving operational efficiency, reducing costs, enhancing safety, and enabling data-driven decision-making. As industrial systems become more interconnected and intelligent, companies are experiencing measurable improvements in uptime, performance, and profitability.

Below are the key benefits of adopting IIoT, along with data points, real-world examples, and industry use cases.

H2: Top Business Benefits of IIoT

1. Predictive Maintenance

Instead of performing maintenance on a fixed schedule, IIoT allows businesses to monitor equipment in real time and predict failures before they happen.

- Result: Reduced downtime and extended asset life

- Stat: According to Deloitte, predictive maintenance can reduce maintenance costs by 25%, unplanned outages by 70%, and breakdowns by 75%.

Example: A manufacturing plant uses vibration sensors on motors. When a bearing starts to wear down, the system flags the anomaly, and the maintenance team replaces it before it causes a shutdown.

2. Improved Operational Efficiency

With real-time data from IIoT systems, industries can optimize production lines, reduce energy waste, and streamline workflows.

- Factory floor automation can adjust machine speeds based on load.

- Smart energy grids can optimize power distribution dynamically.

Case Study: General Electric’s use of IIoT in their gas turbines improved fuel efficiency by 3%, resulting in millions of dollars in annual savings.

3. Enhanced Safety and Compliance

IIoT systems can monitor environmental conditions, machinery performance, and worker safety in hazardous environments.

- Real-time alerts for gas leaks, overheating, or unsafe operations

- Automatic compliance reporting to meet industry regulations (e.g., OSHA, ISO)

Example: In oil and gas, IIoT-enabled wearables track worker location and vital signs, sending alerts if a fall or health event is detected.

4. Better Decision-Making with Data Analytics

IIoT platforms generate vast amounts of operational data, enabling organizations to make informed, data-driven decisions.

- Analyze trends over time to improve yield

- Identify process inefficiencies through historical reports

- Use AI to simulate different operational scenarios

“Data is the new oil — but only when refined. IIoT systems turn raw machine data into insights that drive strategic value.”

— IBM Industry Insights Report

5. Supply Chain Visibility and Optimization

With sensors and tracking systems across the supply chain, companies can:

- Track goods in real time

- Monitor storage conditions (temperature, humidity)

- Predict and respond to delays or disruptions

Table: IIoT in Supply Chain Optimization

| Challenge | IIoT Solution | Benefit |

|---|---|---|

| Unknown inventory levels | Smart shelves, RFID tracking | Reduced stockouts |

| Cold chain spoilage | Temperature sensors in transit | Improved product quality |

| Logistics inefficiencies | GPS fleet tracking and route analytics | Lower fuel costs, faster delivery |

6. Reduced Energy Consumption

IIoT enables smart energy management by analyzing equipment usage and optimizing power loads.

- Shut down idle machines automatically

- Adjust HVAC or lighting systems based on usage

- Monitor energy-intensive processes

Stat: Schneider Electric reported energy savings of 20% in factories using IIoT-based energy optimization tools.

7. Scalability and Flexibility

IIoT allows businesses to scale operations without overhauling infrastructure. With modular sensor networks, they can expand monitoring and control to new machines, sites, or systems as needed.

Industry-Specific Benefits of IIoT

| Industry | Key Benefits |

|---|---|

| Manufacturing | Reduced downtime, quality control, smart automation |

| Agriculture | Crop monitoring, precision irrigation, yield tracking |

| Logistics | Fleet management, cold chain, route optimization |

| Healthcare | Equipment tracking, patient monitoring, smart alerts |

| Energy | Grid monitoring, load balancing, predictive outages |

Frequently Asked Questions (FAQs)

How does IIoT reduce costs?

By enabling predictive maintenance, optimizing energy use, and reducing waste, IIoT helps industries cut operating costs significantly.

Is IIoT only for large enterprises?

No. While adoption started with large corporations, smaller and mid-sized businesses are now leveraging IIoT through affordable, modular solutions.

What’s the ROI of IIoT?

ROI varies by industry and implementation, but studies show payback within 6–24 months, depending on the use case.

Challenges and Risks of IIoT Implementation

What to watch out for when deploying the Industrial Internet of Things

While the Industrial Internet of Things (IIoT) brings enormous advantages, its deployment isn’t without complexity. Organizations often encounter technical, operational, security, and cultural challenges that must be addressed strategically for IIoT initiatives to succeed.

Understanding the barriers and risks associated with IIoT can help businesses mitigate failure, reduce costs, and accelerate ROI.

H2: Key IIoT Challenges Industries Face

H3: 1. Cybersecurity and Data Privacy Risks

Industrial environments are prime targets for cyberattacks — especially when critical infrastructure is involved. As IIoT systems bring more devices online, the attack surface grows significantly.

Risks include:

- Unauthorized access to critical systems

- Ransomware targeting operational technology (OT)

- Data breaches of sensitive sensor and equipment data

Stat: IBM reports that the average cost of a data breach in the industrial sector reached $4.45 million in 2024, with operational downtime being the largest contributor.

Solutions:

- End-to-end encryption of IIoT data

- Zero-trust security models

- Regular patching of connected devices

- Network segmentation (IT vs OT)

H3: 2. Legacy Infrastructure Integration

Many industrial environments run on legacy equipment that was never designed to connect to the internet. Retrofitting or upgrading these systems can be costly and technically difficult.

Common problems:

- Lack of APIs or interfaces to collect data

- Incompatibility with modern protocols

- Limited data granularity from older machines

Strategies:

- Use IIoT gateways to bridge modern systems with legacy PLCs

- Gradual rollout with hybrid integration models

- Partner with vendors that offer industrial protocol support (e.g., Modbus, OPC-UA)

H3: 3. High Upfront Investment Costs

Although IIoT promises long-term savings, the initial investment in hardware, connectivity, analytics, and staff training can be substantial — especially for large-scale rollouts.

Cost contributors:

- Sensor installation and calibration

- Edge computing and cloud platform subscriptions

- Hiring or training data science and IT teams

Mitigation:

- Start with small pilot projects focused on high-ROI use cases

- Leverage government or industry grants (e.g., Industry 4.0 incentives)

- Choose flexible, modular platforms that scale over time

H3: 4. Data Overload and Poor Data Quality

One of the paradoxes of IIoT is that while it offers more data, too much low-quality or unstructured data can overwhelm systems and teams.

Common issues:

- Duplicate, noisy, or incomplete data

- Lack of standards across devices

- Poor contextualization (data without process insight)

Solutions:

- Implement data governance frameworks

- Use edge processing to filter noise before data hits the cloud

- Standardize sensor configurations and metadata tagging

H3: 5. Skills and Organizational Readiness

IIoT requires cross-functional expertise, including OT engineers, IT staff, data analysts, cybersecurity experts, and change management leaders. Many companies lack the right mix of skills.

“The skills gap is one of the top barriers to IIoT adoption. Upskilling and cross-training are essential to digital transformation.”

— Capgemini Research Institute

Recommendations:

- Create cross-disciplinary IIoT implementation teams

- Invest in workforce upskilling programs

- Collaborate with external IIoT consultants or vendors

H3: 6. Lack of Standardization and Interoperability

The industrial IoT landscape is fragmented, with multiple vendors, platforms, and proprietary technologies. Without standardized protocols, devices may not communicate effectively.

Example:

- A sensor from Vendor A may not transmit data in a format readable by Vendor B’s analytics platform.

Approach:

- Prioritize vendors that support open standards (e.g., MQTT, OPC-UA, ISO/IEC)

- Invest in middleware or platforms that enable interoperability

- Advocate for industry-wide adoption of common data schemas

Frequently Asked Questions (FAQs)

Is IIoT secure enough for critical infrastructure?

IIoT can be secure, but only when cybersecurity is built-in from day one. This includes network segmentation, device authentication, and proactive monitoring.

What’s the biggest challenge in implementing IIoT?

For most companies, the biggest challenge is integrating IIoT with legacy systems, followed closely by cybersecurity concerns and skills gaps.

Can small manufacturers afford to adopt IIoT?

Yes, by starting small — such as retrofitting key machines with sensors — small manufacturers can see quick ROI and expand gradually.

Key Use Cases and Applications of IIoT in Industry

Real-world examples of the Industrial Internet of Things at work

The Industrial Internet of Things (IIoT) is not a futuristic concept — it’s already transforming industries around the globe. By enabling intelligent, connected operations, IIoT is solving real-world problems and driving measurable results.

In this section, we’ll explore specific IIoT use cases across different sectors, supported by data, case studies, and the latest applications in the field.

H2: IIoT in Manufacturing (Smart Factories)

Smart manufacturing, also known as Industry 4.0, is one of the most prominent IIoT applications.

Use Cases:

- Predictive maintenance to avoid downtime

- Quality control using AI and vision systems

- Real-time production monitoring

- Digital twins for equipment simulation and optimization

Case Study: Siemens Electronics Factory (Amberg, Germany)

- Uses 1,000+ sensors across production lines

- 99.99885% product quality rate

- Production efficiency improved by 25%

- Automated issue detection and resolution

“The fusion of digital and physical systems through IIoT allows us to see what’s happening and what will happen — then act on it before problems arise.”

— Klaus Helmrich, Siemens AG

H2: IIoT in Energy and Utilities

IIoT plays a key role in managing distributed energy resources, optimizing grids, and monitoring equipment.

Applications:

- Smart meters for usage tracking

- Grid load balancing in real time

- Wind turbine performance analytics

- Remote asset monitoring in solar or oil installations

Example: Duke Energy (USA)

- Uses IIoT sensors to monitor grid transformers

- Reduced outage response time by 40%

- Predicts transformer failures weeks in advance

H2: IIoT in Transportation and Logistics

Supply chain and fleet operations are becoming more efficient and transparent with IIoT.

Applications:

- Fleet tracking with GPS and telematics

- Cold chain monitoring for perishable goods

- Predictive maintenance for vehicles

- Asset tracking with RFID and geofencing

Stat: Companies using IIoT in logistics reduce operational costs by up to 20%, according to DHL.

Real-world Example: Maersk Shipping

- Implements IIoT for container monitoring

- Tracks temperature, humidity, and location

- Minimizes spoilage in refrigerated goods transport

H2: IIoT in Agriculture (Smart Farming)

IIoT allows farmers to make data-driven decisions and automate various aspects of farming.

Use Cases:

- Soil sensors for moisture and pH tracking

- Weather-based irrigation systems

- Livestock monitoring with smart collars

- Drone-based crop analysis

Case Study: John Deere

- Tractors with IIoT sensors optimize planting patterns

- Yield improvements of up to 15% per acre

- Reduced seed and fertilizer waste

H2: IIoT in Healthcare and Medical Equipment

Though less industrial, medical systems increasingly rely on IIoT for device monitoring, patient care, and operational efficiency.

Applications:

- Remote patient monitoring devices

- Asset tracking for critical equipment (e.g., ventilators)

- Environmental monitoring in labs and storage

Example: Cleveland Clinic

- Tracks real-time usage of medical equipment

- Reduces search times by over 30%

- Improves patient outcomes and staff efficiency

H2: IIoT in Oil, Gas, and Mining

In high-risk, remote environments, IIoT brings safety, automation, and remote visibility.

Applications:

- Pipeline monitoring for leaks or pressure anomalies

- Worker safety wearables

- Drone-based inspection of rigs and sites

- Autonomous equipment operation in hazardous zones

Stat: Chevron uses IIoT to monitor over 4,000 pieces of equipment, leading to a 15% reduction in unscheduled downtime.

Summary Table: IIoT Use Cases by Industry

| Industry | Primary IIoT Applications |

|---|---|

| Manufacturing | Predictive maintenance, quality control, robotics, digital twins |

| Energy | Grid monitoring, smart meters, renewable optimization |

| Logistics | Fleet tracking, cold chain, inventory visibility |

| Agriculture | Precision irrigation, crop analytics, livestock monitoring |

| Healthcare | Remote monitoring, equipment tracking, environmental sensors |

| Oil & Gas | Pipeline integrity, worker safety, rig automation |

Frequently Asked Questions (FAQs)

Which industries benefit most from IIoT?

IIoT benefits many sectors, but its impact is most pronounced in manufacturing, logistics, energy, agriculture, and healthcare.

Are there low-cost IIoT use cases for small businesses?

Yes. Simple sensor networks for machine monitoring, energy usage tracking, or inventory control can offer fast ROI for small and mid-sized businesses.

How fast can IIoT deliver measurable results?

Most companies begin to see benefits like downtime reduction or efficiency gains within 6 to 12 months of initial implementation.

IIoT Technologies: Core Tools Powering Smart Industry

A breakdown of the technologies that make the Industrial Internet of Things possible

The Industrial Internet of Things (IIoT) is not a single technology — it’s an ecosystem. It combines hardware, software, connectivity, and analytics to digitize and automate the physical world in industrial environments.

In this section, we’ll break down the key IIoT technologies, how they work together, and why each is crucial to building and scaling industrial IoT systems.

H2: Core Technologies Behind IIoT

H3: 1. Sensors and Actuators

At the heart of every IIoT system are smart sensors that collect real-world data and actuators that enable physical responses.

Common IIoT Sensors:

- Temperature sensors

- Vibration sensors

- Pressure transducers

- Optical and motion detectors

- Proximity and position sensors

- Flow meters

Actuators convert data-driven commands into physical actions — for example, adjusting a valve, moving a robotic arm, or changing motor speed.

Fact: Modern sensors can detect changes in the micron scale and transmit data every millisecond, making real-time industrial automation possible.

H3: 2. Edge Computing Devices

Edge computing processes data near the source (the “edge”) rather than sending all data to the cloud. This reduces latency, bandwidth usage, and reaction time — critical for industrial systems.

Benefits:

- Enables local, real-time decisions

- Filters and pre-processes raw data

- Reduces cloud dependency and costs

Example: A vibration anomaly is detected by a sensor; an edge device instantly commands a machine shutdown to prevent damage — all without needing cloud access.

H3: 3. Industrial Gateways

These are the bridges between OT (Operational Technology) and IT systems. Gateways collect data from sensors and machines, convert it into usable formats, and route it to the cloud or edge devices.

Functions:

- Protocol translation (e.g., Modbus to MQTT)

- Local data aggregation

- Secure data transmission

Stat: 72% of IIoT deployments use edge gateways to connect legacy PLCs to modern cloud analytics tools (source: IIoT World, 2024).

H3: 4. Connectivity Protocols and Networks

Robust connectivity is the foundation of IIoT. It allows for seamless data flow across devices and systems.

Common Connectivity Options:

| Protocol/Network | Use Case | Range | Power Efficiency |

|---|---|---|---|

| Ethernet | Industrial automation, factories | Short | High |

| Wi-Fi | Warehouses, indoor environments | Medium | Medium |

| 5G | Real-time applications, remote ops | Wide | High |

| LoRaWAN | Agriculture, smart cities | Very Wide | Very High |

| NB-IoT | Utilities, metering | Wide | High |

| Bluetooth LE | Wearables, close-range sensors | Short | Very High |

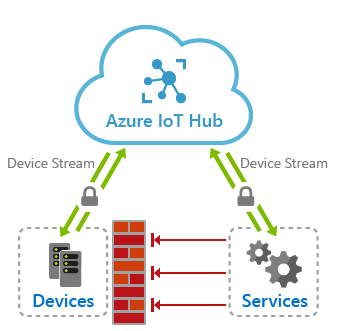

H3: 5. Cloud Platforms and Big Data Storage

Cloud computing enables the storage, processing, and visualization of vast volumes of IIoT data. This is where long-term analysis, AI models, and centralized dashboards operate.

Leading IIoT Cloud Platforms:

- Amazon Web Services (AWS) IoT

- Microsoft Azure IoT Hub

- Google Cloud IoT Core

- IBM Watson IoT

These platforms offer:

- Scalable storage

- Advanced analytics

- Device management

- Security features

- API integrations

H3: 6. Artificial Intelligence and Machine Learning

IIoT systems generate massive amounts of time-series data AI and ML models are essential to make sense of it, detect patterns, and predict future outcomes.

Applications:

- Predictive maintenance

- Anomaly detection

- Quality forecasting

- Autonomous control systems

Example: An ML model trained on years of turbine vibration data can detect early signs of failure weeks before a human operator could.

H3: 7. Digital Twins

A digital twin is a virtual replica of a physical asset, system, or process. It allows companies to simulate operations, test changes, and monitor performance in real time.

Use Cases:

- Simulating equipment stress under different loads

- Optimizing production lines

- Training AI systems on virtual environments

Fact: According to Gartner, by 2026, over 75% of organizations using IIoT will deploy at least one digital twin to improve operational efficiency.

H3: 8. Cybersecurity Solutions for IIoT

Industrial environments are high-risk targets. IIoT cybersecurity requires multi-layered protection from the device level to the cloud.

Key Tools:

- Device authentication and access control

- Encrypted data transmission (TLS, VPN)

- Intrusion detection systems (IDS)

- Zero-trust network models

“Security must be embedded into every layer of the IIoT stack not added as an afterthought.”

Cisco Industrial Security Report

Frequently Asked Questions (FAQs)

What are the most important technologies in IIoT?

Sensors, edge computing, AI, cloud platforms, and secure connectivity form the backbone of most IIoT deployments.

How do cloud and edge computing work together in IIoT?

Edge computing handles time-sensitive tasks locally, while the cloud provides storage, historical analysis, and large-scale AI modeling.

Are digital twins and IIoT the same thing?

No, but they complement each other. Digital twins simulate real-world systems, while IIoT feeds them real-time data to keep them accurate and useful.

How to Implement IIoT in Your Business: A Step-by-Step Guide

A practical roadmap for deploying the Industrial Internet of Things successfully

Adopting the Industrial Internet of Things (IIoT) requires more than buying a few sensors and connecting them to the cloud. It’s a strategic transformation that touches technology, people, processes, and infrastructure.

Whether you’re in manufacturing, energy, logistics, or agriculture, this guide outlines a step-by-step approach to implementing IIoT with minimal risk and maximum value.

H2: Step 1: Define Clear Business Objectives

Before touching any technology, start with the “why.”

Ask:

- What specific pain points are we trying to solve?

- Do we want to reduce downtime, cut energy costs, improve product quality?

- What KPIs will define success?

Example Goals:

- Reduce unplanned machine downtime by 30% within 12 months

- Cut energy consumption in HVAC systems by 20%

- Improve product defect detection rate by 40%

Tip: Align your IIoT goals with broader business goals like sustainability, profitability, and operational excellence.

H2: Step 2: Conduct a Readiness Assessment

Evaluate your current technical infrastructure, workforce capabilities, and organizational maturity.

Assess:

- Are your machines IIoT-ready (smart-enabled or upgradeable)?

- Do you have existing SCADA or MES systems?

- Is your IT/OT team capable of managing new technologies?

- Are your networks secure and scalable?

Tool: Use a readiness checklist or digital maturity model to benchmark your starting point.

H2: Step 3: Start with a Pilot Project

Instead of a full rollout, begin with a small, manageable pilot project targeting a single high-ROI use case.

Characteristics of a good pilot:

- Easy to measure results

- Limited scope and cost

- Minimal disruption to operations

- Strong stakeholder support

Example: Monitor vibration data on one critical motor using sensors and an edge analytics device to trigger maintenance alerts.

Key Pilot Metrics:

| Metric | Goal |

|---|---|

| Uptime increase | +10–30% |

| Maintenance cost reduction | –15–25% |

| Payback period | <12 months |

H2: Step 4: Choose the Right IIoT Platform and Partners

You’ll need an IIoT platform to collect, process, visualize, and analyze your data. Choose one based on scalability, integration capabilities, and industry fit.

Consider:

- Compatibility with existing equipment (PLC, SCADA)

- Support for industry protocols (OPC-UA, MQTT)

- Cloud/edge hybrid capabilities

- Cybersecurity features

Popular IIoT Platforms:

- AWS IoT Greengrass

- Microsoft Azure IoT Hub

- Siemens MindSphere

- PTC ThingWorx

- GE Predix

Also, identify integration partners, solution vendors, and consultants to support implementation.

H2: Step 5: Ensure Robust Cybersecurity Measures

Security must be built in from the start, not added later.

Core Security Practices:

- Network segmentation (IT vs OT)

- Device identity and authentication

- Encrypted communication (TLS, VPNs)

- Role-based access control

- Regular firmware updates

Stat: According to Palo Alto Networks, 60% of IIoT deployments face security vulnerabilities due to poor device-level protections.

H2: Step 6: Train Your Workforce

IIoT systems are only as powerful as the people who use them.

Training should cover:

- IIoT basics and system usage

- Data interpretation and decision-making

- Cybersecurity awareness

- Maintenance of connected devices

Encourage collaboration between IT and OT teams to foster innovation and minimize conflicts.

Tip: Offer cross-functional training programs and certifications (e.g., ISA, IoT Analytics Academy).

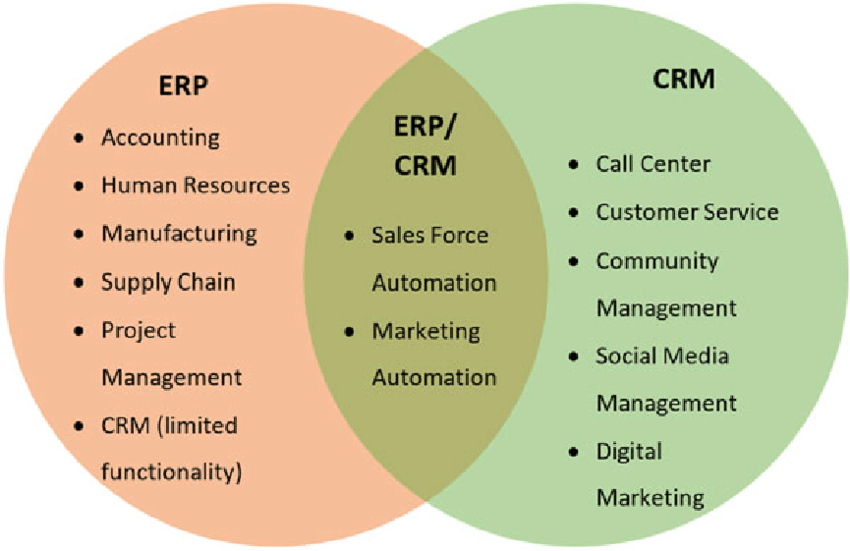

H2: Step 7: Scale Strategically

Once your pilot shows success, plan your scaling phase:

- Expand to other machines, lines, or facilities

- Automate more processes (e.g., quality control, inventory)

- Integrate IIoT with enterprise systems like ERP, MES, or CRM

Track performance through real-time dashboards and continue to optimize based on evolving business goals.

Step-by-Step Summary Table

| Step | Description |

|---|---|

| 1. Define Objectives | Set measurable, outcome-based goals |

| 2. Assess Readiness | Evaluate tech, people, and process maturity |

| 3. Launch Pilot | Start small, monitor KPIs, and measure ROI |

| 4. Choose Platforms | Select tools, vendors, and integration partners |

| 5. Secure the System | Embed cybersecurity from edge to cloud |

| 6. Train Staff | Upskill IT, OT, and operations teams |

| 7. Scale Up | Expand across assets, sites, or processes |

Frequently Asked Questions (FAQs)

What’s the best way to start IIoT adoption?

Start with a well-defined use case, a small pilot project, and a measurable outcome. Don’t try to digitize everything at once.

Do I need to replace all my existing equipment?

No. Many legacy machines can be retrofitted with sensors or connected via IIoT gateways. Start by adding intelligence to your most critical assets.

How long does IIoT implementation take?

Pilots can be launched in 3–6 months, while full-scale deployment may take 12–24 months, depending on complexity and scope.