The term 9.0 13 insert refers to a specific classification or measurement of an insert, often used in precision tooling, engineering, or manufacturing applications. While the designation may seem cryptic at first glance, it typically relates to the dimensions or specifications that correspond to the insert’s compatibility with tools or machines, such as cutting tools, drill bits, or CNC machines. This designation ensures the correct insert fits securely, operates efficiently, and maintains the desired tolerance and output.

In most applications, inserts like the 9.0 13 are used in tool holders, machining heads, or industrial setups where high accuracy and durable performance are essential. The insert may be used for turning, milling, grooving, threading, or boring operations, depending on its geometry, coating, and grade.

Understanding the 9.0 and 13 in the Designation

- 9.0 often represents the insert width, thickness, or minor diameter in millimeters.

- 13 usually corresponds to the insert’s length, major diameter, or engagement measurement, also in millimeters.

However, it’s important to note that 9.0 13 insert can vary by industry and manufacturer. For instance:

- In metalworking, this could refer to a carbide turning insert with specific cutting angles.

- In woodworking, it may be a blade or cutter insert sized for a precise routing or shaping tool.

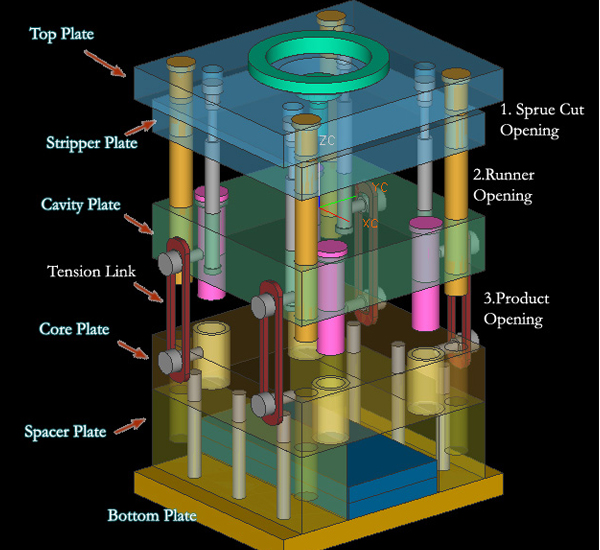

- In injection molding or tool & die, it could be a dowel insert or ejector component with a 9.0 mm shaft and 13 mm head.

Always refer to the manufacturer’s specification sheet or a trusted dimensional standard chart before selecting a 9.0 13 insert.

Why the 9.0 13 Insert Is Important

Precision inserts like the 9.0 13 are critical to maintaining accuracy, repeatability, and performance in industrial and technical settings. Here’s why this matters:

1. Maintains Production Tolerance

Small variations in insert size can lead to:

- Misalignment

- Vibrations during machining

- Poor surface finish

- Rejected parts

2. Ensures Tool Compatibility

Choosing the wrong insert can damage your equipment. The 9.0 13 insert ensures proper fit with compatible toolholders or machinery slots.

3. Cost Efficiency

Using the correct insert size (like 9.0 13) reduces waste, tool change downtime, and scrap materials.

4. Safety

Precision-matched inserts reduce the chance of insert slippage, tool breakage, or operator injury.

Common Industries That Use 9.0 13 Inserts

| Industry | Use Case |

|---|---|

| Metalworking | Turning, threading, grooving inserts for CNC tools |

| Woodworking | Blade inserts in routers or shapers for decorative edge work |

| Automotive | Inserted dies for body parts, mold pieces for interior trimming tools |

| Aerospace | Precision parts with tight tolerances for high-stress components |

| Plastic Molding | Core pins, ejector sleeves, insert molding operations |

Types of 9.0 13 Inserts and Their Variations

The term 9.0 13 insert doesn’t refer to just one type. It can be part of several types depending on the cutting action, material used, or application.

By Function:

- Turning Inserts: Used for lathe operations.

- Milling Inserts: Designed for high-speed cutting and surfacing.

- Threading Inserts: Form precise thread profiles on various materials.

- Drilling Inserts: Enhance chip control and reduce heat generation.

By Material:

- Carbide Inserts: Ideal for durability and heat resistance.

- Cermet Inserts: For better surface finish in steel.

- Ceramic Inserts: High-speed finishing for hard materials.

- Coated Inserts: TiAlN or PVD coatings for extended tool life.

By Geometry:

- Square, triangular, round, and diamond-shaped depending on cutting direction and part geometry.

Who Should Use a 9.0 13 Insert?

The 9.0 13 insert is not a one-size-fits-all component—it’s specifically designed for users who demand precision, durability, and repeatable performance in their manufacturing or machining processes. From small workshops to large-scale industrial operations, this insert size plays a crucial role in applications where dimensions matter.

Let’s explore the types of professionals and industries that benefit from using a 9.0 13 insert and what sets it apart from other sizes or variants.

1. CNC Machinists and Metalworking Professionals

In precision machining environments, where tolerances are often within microns, using the wrong insert can lead to major production flaws. For CNC machinists, the 9.0 13 insert size is ideal for tools that require:

- Stable insert fit

- Reduced chatter and vibration

- High-speed cutting compatibility

- Extended tool life

For example, in a CNC turning setup, the 9.0 13 insert may be used in:

- Indexable toolholders

- Threading tools

- Grooving cutters

A machinist using stainless steel stock may choose a coated carbide 9.0 13 insert to withstand the material’s hardness and heat generation during machining.

2. Woodworkers and Furniture Designers

A 9.0 13 woodworking insert may be used in:

- Cabinet door shapers

- Router bits

- Jointing or planing tools

Especially for high-end furniture or custom cabinetry, the dimensional accuracy of the insert directly affects the quality of the final product.

- A core pin insert

- An ejector sleeve

- A mold cavity insert

The size ensures the insert can be replaced or retooled without affecting the mold’s overall dimensions—crucial for multi-cavity molds and high-volume production.

4. Engineers and R&D Technicians

During product prototyping or part testing, engineers may require interchangeable inserts for modular designs. A 9.0 13 insert offers:

- Precision fit

- Compatibility with multi-axis test rigs

- Minimal thermal expansion

These benefits allow R&D teams to simulate real-use scenarios with reliable component integration.

5. Educational Institutions and Vocational Training Centers

Machining and engineering institutes often standardize insert sizes for learning purposes. The 9.0 13 insert is commonly chosen because it:

- Is versatile and applicable across disciplines

- Fits many commonly used training machines

- Is cost-effective for bulk procurement

It also teaches students about standard tooling practices, insert nomenclature, and precision metrology.

When Should You Choose a 9.0 13 Insert Over Another Size?

Choosing the correct insert size depends on:

| Criteria | 9.0 13 Insert Is Ideal When… |

|---|---|

| Application size | Medium-scale cutting or shaping is required |

| Toolholder design | The insert cavity specifically fits 9.0 mm x 13 mm inserts |

| Precision needs | Tolerance requirements are strict |

| Volume of production | High output demands minimal tool change downtime |

| Budget efficiency | Standardized inserts lower replacement and inventory cost |

Summary: Is the 9.0 13 Insert Right for You?

You should consider using a 9.0 13 insert if:

- You prioritize dimensional stability.

- Your tools or holders are designed for this specific spec.

- You’re operating in industries where surface finish, fit, and longevity directly affect performance or profit.

Choosing the wrong insert, even by a single millimeter, could cause misalignments, inefficiencies, or even safety hazards. Always verify tool compatibility, material match, and application requirements before purchase.

Main Types of 9.0 13 Inserts

While the term 9.0 13 insert refers to a specific size configuration, there is a broad variety of insert types within this classification. Each type serves a unique function depending on its geometry, coating, material composition, and intended use.

Understanding these types is essential when choosing the correct 9.0 13 insert for your tool or application. Selecting the wrong type can lead to premature wear, poor surface finishes, or even tool failure.

1. Standard Factory Inserts

These are the most commonly available inserts, manufactured with fixed specifications and often mass-produced for general use.

Key Features:

- Precise size tolerances to fit into standard holders or heads

- Typically made of uncoated carbide or basic HSS (High-Speed Steel)

- Cost-effective for low to medium-volume operations

Best For:

- General-purpose machining

- Wood shaping and edge forming

- Simple plastic or aluminum part trimming

Note: These inserts often require more frequent replacement than premium or coated types.

2. Coated Inserts (TiAlN, CVD, PVD Coatings)

Coated inserts are specially treated with heat-resistant, wear-resistant films to improve performance and longevity.

Types of Coatings:

- TiN (Titanium Nitride): Enhances hardness, ideal for steel cutting.

- TiAlN (Titanium Aluminum Nitride): Excellent heat resistance at high speeds.

- PVD/CVD coatings: Used for specialized applications and chip control.

Benefits:

- Withstand high-speed machining without losing temper

- Reduce built-up edge during cutting

- Lower friction, resulting in better surface finish

Best For:

- Hard materials like stainless steel, cast iron, or heat-treated alloys

- High-production environments like automotive or aerospace

3. Precision Ground Inserts

These inserts are finely ground on all sides to ensure tight tolerance for critical applications.

Why Use Precision Ground Inserts?

- Improved surface finish

- Consistent repeatability for automated manufacturing

- Better edge retention due to exact sharpening

Common Industries:

- Medical device manufacturing

- Aerospace engineering

- Mold-making and die industries

4. Modular and Replaceable Inserts

These are inserts designed to be easily removed and replaced from a reusable insert holder or tool body.

Advantages:

- Quick-change ability during long production runs

- Lower long-term cost due to reusable tool body

- Great for CNC and robotic operations

Design Examples:

- Indexable inserts with notched or pinned corners

- Modular router heads in woodworking

These inserts may come in standard 9.0 x 13 mm specs, with the geometry customized to specific operations (e.g., square for grooving, round for profiling).

5. Specialty or Custom Inserts

In some cases, off-the-shelf inserts won’t meet unique production needs. That’s where custom 9.0 13 inserts come in.

Custom Insert Use Cases:

- Proprietary tooling systems

- Unusual geometries

- Extreme environments (chemical exposure, high loads)

Materials Used:

- Polycrystalline diamond (PCD)

- Cubic boron nitride (CBN)

- Advanced ceramics

These inserts may be significantly more expensive but deliver unmatched performance, wear resistance, and thermal stability.

Comparison Table: Types of 9.0 13 Inserts

| Insert Type | Material | Ideal Use Case | Durability | Cost |

|---|---|---|---|---|

| Standard Factory | HSS/Carbide | General-purpose, manual or light-duty | Moderate | Low |

| Coated (TiAlN, etc.) | Carbide w/ Coating | High-speed machining, steel, alloys | High | Medium |

| Precision Ground | Carbide | Surface finish critical work | Very High | High |

| Modular/Replaceable | Carbide/Steel Body | CNC or robotic tool systems | High | Medium |

| Custom or Specialty | PCD, CBN, Ceramic | Harsh environments or unique specs | Extremely High | Very High |

Conclusion of This Section

Whether you are operating in a mass production facility or a custom fabrication shop, understanding the types of 9.0 13 inserts helps you match the right insert to the right task. Choosing the correct type impacts:

- Your final product’s quality

- Tool and machine longevity

- Operational efficiency and cost

Using the wrong insert is not just inefficient—it can be costly and even dangerous.

Key Features to Look for in a 9.0 13 Insert

When selecting a 9.0 13 insert, it’s not enough to simply match the size. The performance, lifespan, and application-specific suitability of your insert heavily depend on several critical features. These characteristics help determine how well the insert will perform under specific machining conditions and how it will affect your end-product quality, operational cost, and tool maintenance.

Below are the most important features to evaluate when choosing a 9.0 13 insert:

1. Material Composition

The base material of the insert directly impacts its:

- Wear resistance

- Thermal stability

- Toughness under load

Common Materials:

- Tungsten Carbide: Industry standard for durability and heat resistance.

- Cermet: Ideal for finishing steel with a great surface finish.

- Ceramics and CBN: Excellent for hardened steels and high-speed finishing.

- Polycrystalline Diamond (PCD): Best for non-ferrous metals, wood, and composites.

Authority Source: Sandvik Coromant – Guide to Insert Materials

2. Coating Type

Insert coatings enhance lifespan and performance by reducing friction and heat buildup.

Popular Coatings:

- TiN (Titanium Nitride): General purpose coating, golden in color.

- TiAlN (Titanium Aluminum Nitride): High-heat resistant, great for stainless and alloys.

- AlTiN: Even more thermally stable, good for dry machining.

- CVD and PVD Coatings: Provide precise layer control for demanding jobs.

Note: Always match the coating with your workpiece material to optimize cutting conditions and tool life.

3. Insert Geometry

Insert geometry determines how the tool cuts, chips, and finishes the material. The 9.0 13 insert comes in multiple profiles, each suited for a particular task.

Key Geometry Factors:

- Shape: Square, round, triangle, rhomboid, or custom

- Edge radius: Affects surface finish and cutting pressure

- Chipbreaker design: Controls chip formation, especially in soft or stringy materials

Well-designed chipbreakers can prevent chip wrapping and reduce machine downtime.

4. Tolerance & Precision Fit

Even a small dimensional mismatch can result in:

- Poor clamping

- Increased vibrations

- Reduced surface finish

- Accelerated wear

Ensure that the tolerance class of the insert matches your toolholder and cutting application. ISO standards define insert tolerances using symbols like M, G, or E (with E being the tightest).

Tip: Refer to ISO 1832 Insert Designation Standards for standardized coding and tolerance ratings.

5. Compatibility and Clamping System

Some 9.0 13 inserts require a top clamp, others a wedge lock, or screw clamping system. Compatibility with your toolholder is non-negotiable.

Things to Check:

- Toolholder brand and model

- Insert seating area and rake angle

- Clamping torque specifications

Always follow your tool manufacturer’s guidelines for insert seating and torque application to prevent cracking or slippage.

6. Durability and Heat Resistance

If you’re running continuous operations or machining hard materials, look for inserts that:

- Have multi-layer coatings

- Support high-speed machining

- Exhibit low thermal deformation

CVD-coated carbide inserts are often the best choice for high-volume industrial applications where performance and consistency are critical.

7. Surface Finish Capability

7. Surface Finish Capability

- Insert nose radius

- Edge treatment

- Cutting edge preparation (honed, chamfered, etc.)

Inserts for finishing typically feature sharp cutting edges, while those for roughing use stronger, blunter profiles.

Comparison Table: Key Features of 9.0 13 Inserts

| Feature | Purpose | Best For |

|---|---|---|

| Material Composition | Determines hardness and heat resistance | All-purpose vs. high-performance cutting |

| Coating Type | Improves wear life and chip flow | Dry machining, alloy cutting |

| Insert Geometry | Affects cutting angle and chip evacuation | Specific tasks: roughing, finishing, etc. |

| Tolerance & Fit | Ensures secure clamping and stable performance | High-speed or high-accuracy jobs |

| Compatibility | Must match with specific holders | Brand-dependent tool systems |

| Heat Resistance | Prevents breakdown during long operations | Continuous cutting, abrasive materials |

| Surface Finish Quality | Controls roughness and quality of cut | Final machining and cosmetic surfaces |

Conclusion of This Section

Selecting the right 9.0 13 insert is more than just choosing a size. You must evaluate a mix of material properties, coating technologies, geometry, and toolholder compatibility to ensure optimal performance.

Taking shortcuts in this step can result in poor productivity, tool failure, or even damage to your machinery. If in doubt, consult manufacturer datasheets, review ISO insert standards, or explore trusted brands like Sandvik Coromant and Kennametal for authoritative specifications.

How to Choose the Right 9.0 13 Insert

Choosing the right 9.0 13 insert requires more than just selecting a standard size—it involves evaluating multiple technical and practical factors based on your machine, material, application, and desired output. Making an informed selection will not only improve your machining performance but also extend tool life, reduce downtime, and ensure optimal surface finishes.

In this section, we will walk you through a step-by-step decision framework to help you confidently choose the ideal 9.0 13 insert for your application.

1. Identify Your Application Type

Before purchasing an insert, you must understand the specific application it’s being used for. Each machining process imposes different demands on the insert.

| Application | Key Considerations |

|---|---|

| Turning | Chip control, edge toughness, surface finish |

| Milling | Insert geometry, heat resistance, cutter body compatibility |

| Drilling | Point geometry, feed rates, coolant support |

| Threading | Profile accuracy, insert orientation, pitch consistency |

| Grooving | Side cutting force, rigidity, groove depth tolerance |

Understanding your process is the first step to determining insert features like coating type, nose radius, and rake angle.

Material Matching Chart:

| Workpiece Material | Recommended Insert Material |

|---|---|

| Aluminum, Copper | PCD or Uncoated Carbide |

| Stainless Steel | TiAlN-Coated Carbide |

| Cast Iron | Ceramic or CVD-Coated Inserts |

| Hardened Steel | CBN or Ceramic |

| Plastics & Composites | Uncoated Carbide or PCD |

| Wood | Solid Carbide or Replaceable Blades |

Learn more about material compatibility from Kennametal’s Material Cutting Guides.

3. Understand Your Machine Tool Compatibility

You must ensure that the insert matches your machine toolholder system and spindle capacity. The 9.0 13 insert must physically fit and be clamped securely to prevent movement under stress.

Key Parameters to Check:

- Insert pocket size on your cutter head or toolholder

- Locking/clamping mechanism (screw, wedge, clamp)

- Max RPM rating of insert vs. machine spindle

- Rake angle support (positive, neutral, negative)

Even a properly sized insert (9.0 mm x 13 mm) will fail if not seated correctly or if it introduces instability.

4. Evaluate Cutting Conditions

You’ll also want to assess:

- Cutting speed (V): Faster speeds require more heat-resistant inserts.

- Feed rate (f): Higher feed rates put more pressure on the edge.

- Depth of cut (d): Deep cuts demand stronger geometry and chip control.

- Coolant usage: Dry machining requires coated inserts for heat management.

For calculating optimal speeds and feeds, consult the Machinery’s Handbook, an industry standard.

5. Consider Surface Finish Requirements

For high-precision parts or cosmetic finishes, choose inserts with:

- Smaller nose radius (e.g., 0.4mm or 0.8mm)

- Sharp, polished cutting edges

- Chipbreakers for thin and continuous cuts

For roughing or interrupted cuts, go for:

- Stronger edge prep (chamfered or honed)

- Larger nose radius

- More aggressive chipbreakers

6. Review Brand Quality and Certifications

Trusted brands often provide:

- Detailed datasheets

- ISO certifications

- Testing reports

- Support for tool life optimization

Some reputable manufacturers offering high-quality 9.0 13 inserts include:

Avoid no-name brands unless accompanied by clear specifications and return policies.

7. Budget & Longevity Trade-Off

Inserts vary widely in price, but cheaper isn’t always better.

Budgeting Tips:

- Economy-grade inserts are good for training or low-priority work.

- Coated premium inserts are more cost-effective over time in high-volume operations.

- Custom inserts may carry high upfront costs but can prevent catastrophic failures in critical parts.

Insert Cost vs. Tool Life Estimate (Example):

| Insert Type | Cost per Insert | Average Tool Life (pcs) | Cost per 1000 pcs |

|---|---|---|---|

| Standard Uncoated | $5 | 100 | $50 |

| TiAlN-Coated Carbide | $12 | 300 | $40 |

| Precision Ceramic | $30 | 800 | $37.50 |

Insert Selection Checklist

Use the following checklist before purchasing:

- Does the insert match the 9.0 x 13 mm requirement?

- Is the insert material appropriate for my workpiece?

- Is the geometry (shape, rake, nose radius) suitable for my process?

- Does it fit securely in my machine’s holder or cutter?

- Is it compatible with my cutting speed and feed rate?

- Will it help me achieve the desired surface finish?

- Is it from a trusted brand or certified source?

Conclusion of This Section

Choosing the right 9.0 13 insert is a multi-factor decision that combines machine compatibility, application-specific needs, cutting parameters, and brand quality. Making the right choice will directly improve:

- Tool life

- Production speed

- Part accuracy

- Operational safety

If you’re unsure, consult with your insert supplier or a technical sales engineer to help match your operation with the best possible insert choice